Short Lead Times for Manufacturing Dietary Supplements - Real or Red Flag?

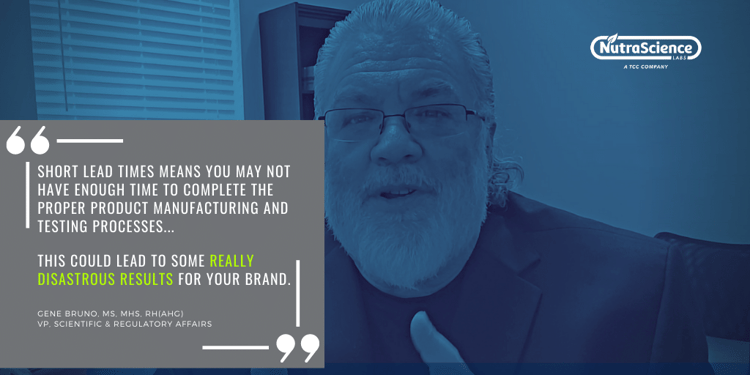

If you’re a dietary supplement brand owner or aspiring to be one, you’ve probably spent time investigating various contract manufacturers (CMs) online or in person. During this process, you may have come across some CMs that offer short lead times (e.g., 4 weeks) for having products manufactured. While really short lead times may sound great, I must warn you that such lead times should be considered a red flag. Here’s why.

[Author's Note - Shortly after publishing this article, the FDA issued a warning letter to a well-known dietary supplement company for having numerous contaminants in its raw materials. You can learn more about this news by visiting NutraIngredients-USA.com.]

Steps for Manufacturing Dietary Supplements

After 40+ years in the dietary supplement industry, I can tell you that there has consistently been a lot of misinformation being propagated about the manufacturing of dietary supplements. The old adage, “If it sounds too good to be true, it probably is”, definitely applies here. Consider that manufacturing dietary supplements at a CM is a process with several steps. Although these steps can be broken down in different ways, here is a general explanation:

- Determining the initial formulation to meet desired label claims

- Sourcing the ingredients that will be used in the formulation

- Testing the raw materials once they arrive

- Conducting bench work / pilot batches

- Manufacturing the production batch of the supplement

- Testing the completed production batch

- Packaging/labeling the finished product

- Shipping the finished product to the customer (you)

Determining the Initial Formulation

Maybe you've come into the process knowing the exact formula you want, including all the component ingredients, or maybe you just know the general claims you want but not the ingredients. If the former, then your conceptual formula still must be adapted to a manufacturing formula with all necessary excipients while determining the number of capsules (or other deliver format) that will be required to fit your formula into each serving. If the latter, then the creation of the conceptual formula with substantiated claims will still need to take place first before adapting it to a manufacturing formulation. This step may take a couple of days, or a couple of weeks (including back and forth time between the CM and you for approval).

Sourcing the Ingredients

Without question, this step is the wild card in the process. Ordering the correct and appropriate ingredients for each formulation not only requires expertise but patience, too. Some ingredients may come from domestic sources, while others come from international sources. In either case and as most people are aware, supply chain issues have been a huge problem since the pandemic. That means that some ingredients that used to take a couple of weeks to obtain, may now take a couple of months—and there’s nothing that anyone can do to change it until things normalize.

Now I've heard some CMs claim that they've compensated by ordered and stocking significantly more of a given raw material so that they don’t run out as soon and must reorder. The problem with this approach is that, unless all that raw material is going to be used in a relatively short period of time, it may sit around for many months. That means that when it is finally used in your formula, the material is older, and your product will have a shorter expiration date as a result (assuming that the CM is being honest and offering full disclosure). In any case, ordering and receiving all the raw materials need for a formula can easily take a couple of months.

Testing the Raw Materials

If a CM is following GMP standards, when a raw material arrives it must be tested to assure potency and safety—including microbiological and heavy metal testing. If the CM has an in-house laboratory, the testing might be quicker, but either way, it will still take 1-2 weeks for the results. To be clear, regulations stipulate that raw materials may not be released into general inventory until they have passed testing.

Conducting Bench Work / Pilot Batches

Once the prior steps are completed, the theoretical paper formula has to graduate to actual bench work and/or a pilot batch to make sure that all the ingredients will fit in the dosage form as planned and will be likely to run correctly during the full production batch. This may take up to a week to complete.Manufacturing the Production Batch

Next is the manufacturing production run. Assuming all of the other steps have been successfully completed, this step doesn’t really take all that long. In fact, it may be completed in as little as a few days or a week.Testing the Completed Production Batch

As with the raw materials, the completed production batch has to be tested to assure safety and any other desired certifications (e.g., gluten-free, etc.). This will likely take another week or so.Packaging / Labeling the Finished Product

Assuming that label art and label printing were completed concurrently with the prior steps, this step will only take a day or two (depending on the order size).Shipping the Finished Product

The amount of time it takes to complete this last step is dependent upon the shipping destination as well as the method of shipping—so anywhere from a few days to a week.Crunch the Numbers and Here's What You'll Find

If you add up the time it takes to complete each of these steps, you can see that it can easily take 12-14 weeks to get the job done correctly and in its entirety. So, a CM claiming to manufacture products in only 4 weeks is either purposely misleading you, or they have an extremely limited scope of what they can actually manufacture for you (e.g., only amino acid products, etc.).

Worse yet, you need to be very careful that a CM offering such short lead times is actually putting all of the listed ingredients in the formula. If you opt to do business with a contract supplement manufacturer that promises shorter-than-average lead times, I highly recommend that you send the finished product out for third-party testing to verify that the formula contains everything that it is supposed to contain.

Last, but not least, I urge you to use this article as a guide when vetting supplement manufacturers. It’s not unreasonable to ask the manufacturer you’re speaking with to walk you through their manufacturing process. If they can’t do it, are unwilling to do it, or struggle to explain it, it should throw up a red flag to not work with them. While you may save time and money on the front end, the damage it could cause in the long run could cause irreparable harm to your brand – not to mention the people that purchase and consume your product!

How can NutraScience Labs Help You?

With over 120 years of nutraceutical industry experience, NutraScience Labs has provided custom supplement contract manufacturing services to more than 2,300 brands globally. Our clients sell their products in popular retail stores and online marketplaces like Amazon, Target, CVS, and Walmart.

As part of our auditing process, we ensure that the facilities we utilize to manufacture your products strictly adhere to the steps I’ve covered above. What’s more, these laboratories operate in the United States and get audited annually to retain their GMP Certification, so you can rest assured that your product will be manufactured according to guidelines mandated by the FDA.

To learn more about how NutraScience Labs can help you create your first product or expand your dietary supplement line, call 855-492-7388 to speak with one of our production specialists or send us your request for a free manufacturing price quote.